Industrial

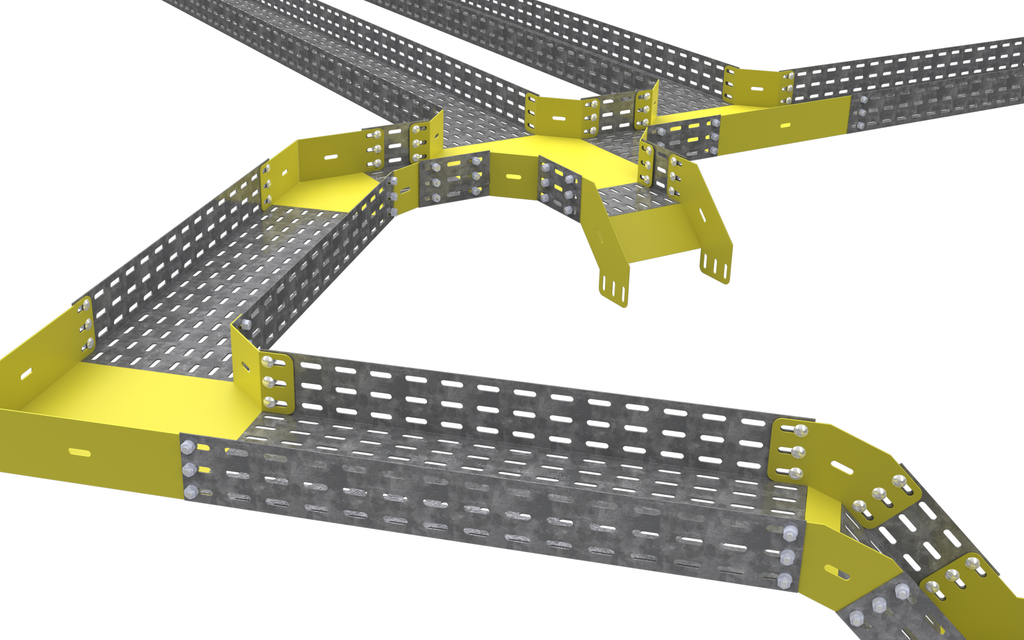

CABLE TRAYS

GF - Carbon steel hot dip galvanized

Satandard: NBR 6323 (Brazil)

Aplications: Products for external use or under medium corrosion.

This process is inherently simple which provides a distinct advantage over other corrosion protection methods.

While the steel in the kettle (450ºC), the iron in the steel metallurgically reacts with the molten zinc to form a tighly-bonded alloy coating that provides superior corrosion protection to steel.

Zinc Layer: 50/60 micra

Complementary Code: GF

More Information: American Galvanizers Association

GE - Carbon steel electrolytic galvanized

Standard: NBR 10476/88

Applications: Products for internal use in areas without corrosion can be specified with electrolytic galvanizing.

Zinc Layer: 8/10 Micra

Complementary code: GE

PZ - Carbon Steel pre galvanized

Standard: NBR 7008 (Brazil)

Application: The continuous hot dip process is a widely used method originally developed over fifty years ago for galvanizing of products such steel, strip and wires.

The molten coating is applied onto the surface of the steel in a continuous process to cleaning. The steel is passed as a continuous ribbon through a bath of moltezinc at speeds up to 20km/minute. Once the product is removed from the bath, high pressure air is used to remove any excess moltenzinc to create a closselly controlled coated thickness. The steel is cooled to allow the metal to solidify on the steel surface, which is done before the steel contacts another roll to avoid transfering or damaging the coating.

Zinc Layer: 18 Micra

Complementary Code: PZ

AI - Stainless steel 304, 316

Standard: ASTM A480 and ASTM A555

EN 10088/1 10088/2 10083/3

Applications: Good general corrosion resistance, good cryogenic toughness, excellent formability and weldabillity.

Limited resistance to stress corrosion weldabillity.

Limited resistance to stress corrosion cracking.

For cable trays are recomended 304 (food & beverage industries) or 316 (oil & gas applications).

Complementay Code: AI 304 or AI 316

More Information: BRITISH STAINLESS STEEL ASSOCIATION

AL - Aluminum Alloy

Standard: ASTM B209

Applications: Alloy 1100 is recommended to use in chemical equipaments,Alloy 5052 has a good resistance to corrosion and because this is used in marine applications, pressure vessels, hardware signs and trucks. Alloy 6063 is applicated in building products, electric an eletronic parts.

Complementary Code: AL

PT - Electrostatic Painting

Standard: NBR 14125 (Brazil)

Applications: Electrostatic painting is a method for painting metals and centain types os plastics. It make use of electrically chraged powders in order to create a sleek and smooth finish and othe design effects.

The electrostatic painting also generall proves to be more durable than other liquid painting plus.

Applications are used is three areas: residential, commercial and industrial.

Exemples: Window frames, light poles, metal doors and jambs, store fronts, industrial piping (specially water pipes)

Coat Layer: 60/80 Micra

Complementary Code: PT